Guides and instructions

From wheel selection to professional techniques, everything you need to know about abrasives

Complete Guide: How to Choose a Cutting Wheel for a Grinder

A comprehensive guide to choosing abrasive wheels. We analyze materials, sizes, markings. From beginner to pro in 15 minutes of reading.

Read the guide For beginners

For beginnersHow to choose a grinding wheel

Petal, fiber, cup - what's the difference and when to use which?

Average

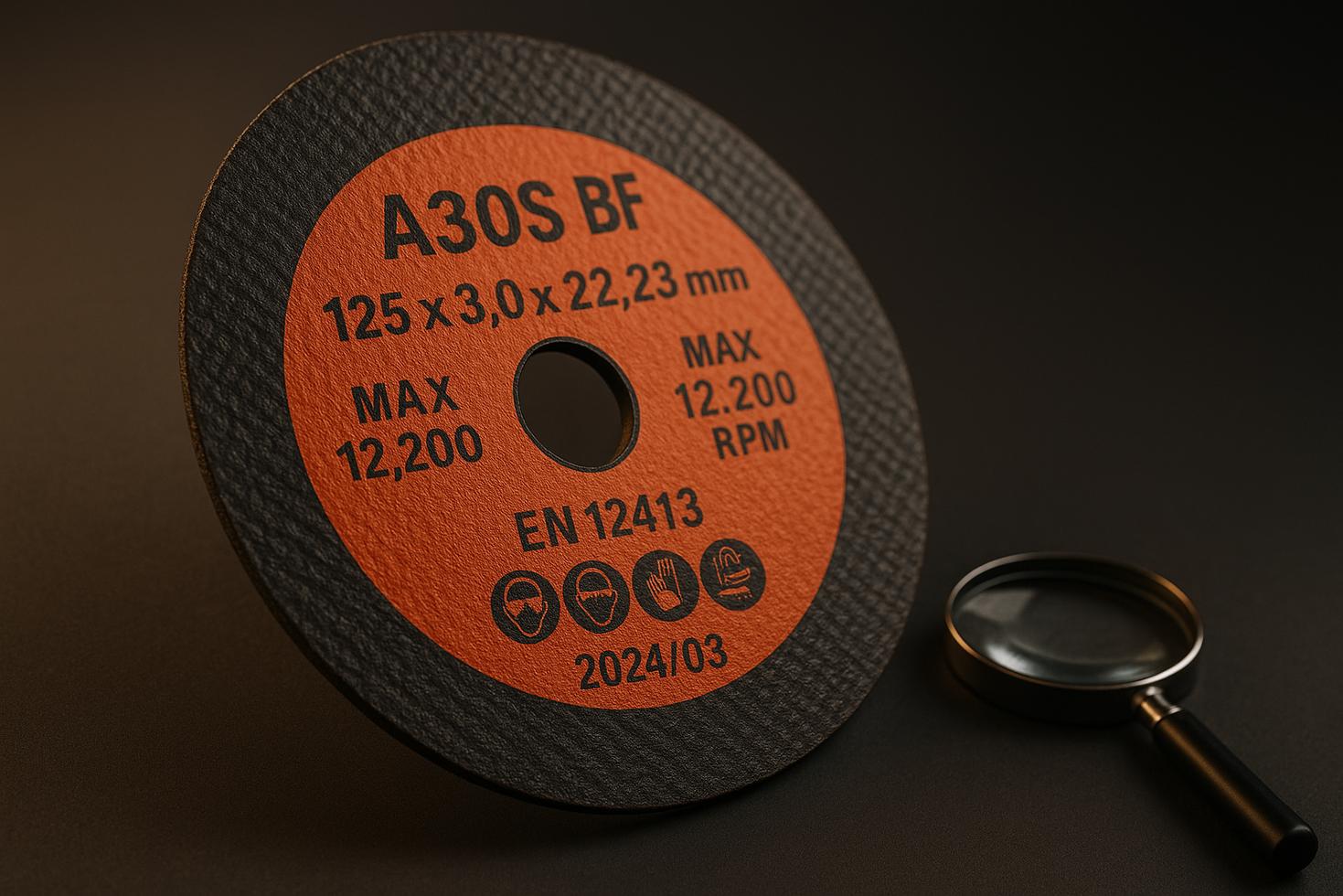

AverageMarking of abrasive wheels

Deciphering the markings on the circle: A, C, grain size, hardness, bond

Video

VideoMetal cutting technique with a grinder

Video tutorial: correct angle, feed rate, cooling

For beginners

For beginnersCutting concrete and stone

Choosing a wheel for stone materials, diamond wheels vs abrasive wheels

Pros

ProsWorking with stainless steel

Features of cutting and grinding stainless steel without contamination

Average

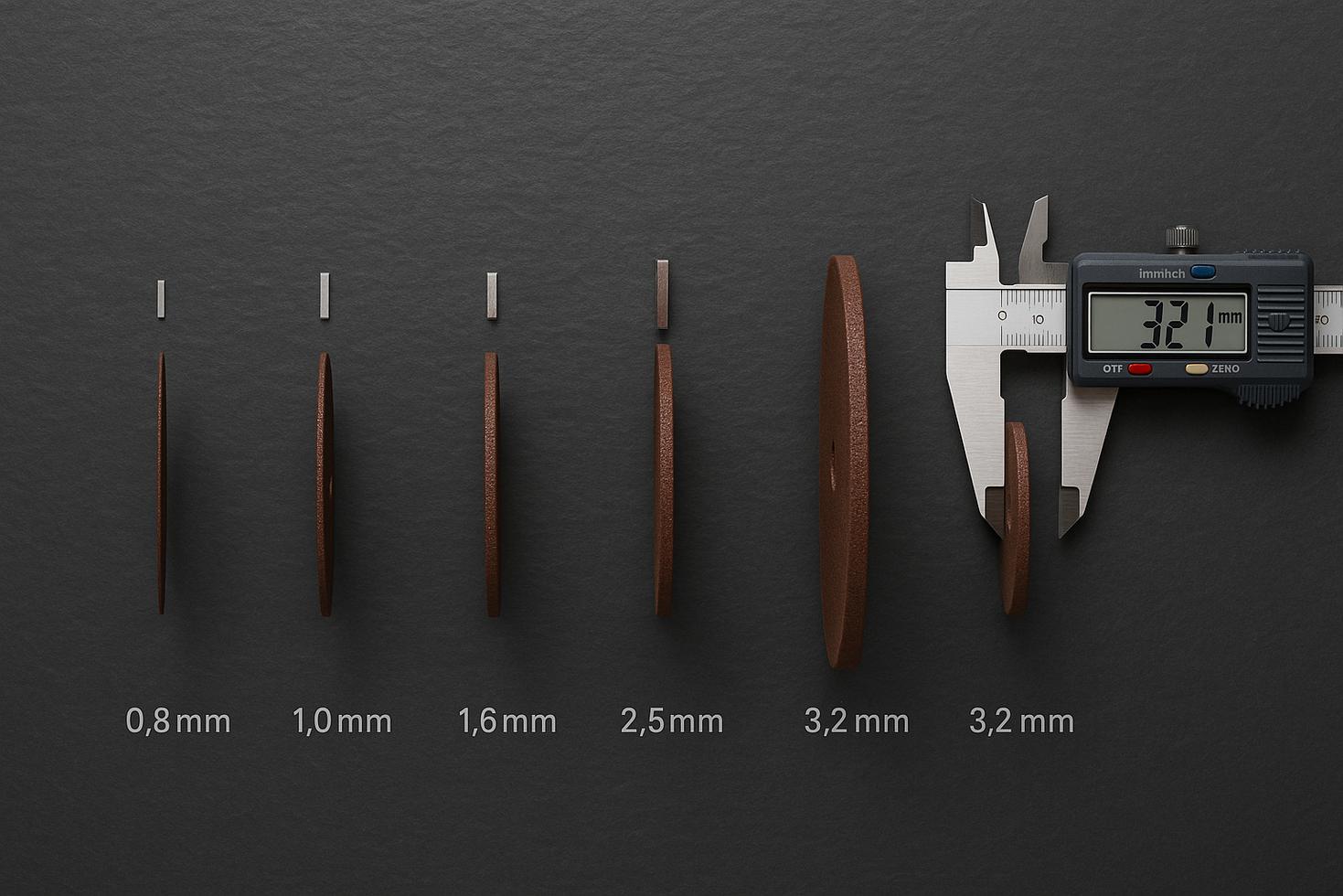

AverageChoosing the thickness of the cutting wheel

1.0, 1.6, 2.5 mm — how thickness affects cutting quality and speed

For beginners

For beginnersStorage of abrasive wheels

How to store circles so they don't lose their properties

Video

VideoGrinding of welds

Video tutorial: surface preparation, wheel selection, technique

Pros

ProsOptimization of abrasive costs

How to reduce cost per lap without losing productivity

Frequently asked questions

Answers to the most popular questions about choosing and using abrasive wheels

How do I choose the right abrasive disc for my job?

The choice of abrasive disc depends on several key factors:

- Processing material: For steel, use aluminum oxide discs (marked A), for stainless steel - zirconium or ceramic discs with the INOX marking, for stone and concrete - silicon carbide discs (marked C).

- Type of operation: For cutting, choose thin discs (0.8-3.0 mm), for grinding, choose thicker grinding discs (4-8 mm) or flap discs.

- Work intensity: For professional use, we recommend the EXTREME or PROFI series with ceramic or zirconium grain.

What is the difference between alumina, zirconia, and ceramic?

Aluminum oxide (Al2O3) is a versatile and most common abrasive. Suitable for general use on steel and non-ferrous metals. Optimal price-performance ratio.

Zirconium (ZrO2)— has higher strength and self-sharpening properties. Ideal for stainless steel and heavy-duty work. Lasts 2-3 times longer than aluminum oxide.

Ceramic grain (SG) is the most technologically advanced and durable abrasive. Provides cool cutting, minimal workpiece heating and maximum productivity. Recommended for heavy metals and professional use.

What grit should I choose for cutting metal?

Grit affects cutting speed and edge quality:

- Coarse grit (24-36): Fast cutting of thick metal (from 10 mm). Higher speed, but coarser edge.

- Medium grit (46-60): Universal option for 3-10 mm metal. Balance of speed and quality.

- Fine grit (80-120): For thin sheet metal and finishing. Clean edge, less burrs.

For most jobs, we recommend grit 46-60 as the optimal compromise.

What is a ligament and how does it affect disk operation?

The bond is the material that holds the abrasive grain in the structure of the disc. The bond determines how quickly the disc wears and how efficiently it works:

- Soft bond: Grain falls out faster, disc is self-sharpening. Cuts better, but wears out faster. Suitable for hard metals.

- Hard bond: Grain holds stronger, disc lasts longer. May overheat when working with hard metals. Suitable for soft metals.

Rule: The harder the metal, the softer the bond, and vice versa.

What is the difference between a cutting wheel and a grinding wheel?

Cutting wheels:

- Thickness: 0.8-3.0 mm

- Working angle: 90° (perpendicular to the surface)

- Purpose: cutting metal, pipes, profiles

- Reinforcement: usually double mesh

Polishing (grinding) wheels:

- Thickness: 4-8 mm

- Working angle: 15-30° to the surface

- Purpose: metal removal, seam cleaning, scale removal

- Reinforcement: reinforced structure for lateral loading

Important: Never use a cutting wheel for grinding - this may lead to destruction of the disc!

How to choose the diameter of the disc for a grinder?

The diameter of the disc must match the power of your grinder:

- 115 mm: For light work, small grinders up to 800 W. Cutting depth up to 25 mm.

- 125 mm: The most popular universal size. Angle grinders 800-1200 W. Cutting depth up to 35 mm.

- 180 mm: For powerful machines 1500-2000 W. Cutting depth up to 55 mm.

- 230 mm: For professional work and large volumes. Angle grinders from 2000 W. Cutting depth up to 70 mm.

Safety: Never remove the protective cover and never use a disc with a larger diameter than the tool allows!

What discs should I use for cutting stainless steel?

For stainless steel, use special discs marked INOX (or AS 46 INOX BF):

- Composition: Iron and sulfur free, which prevents corrosion of the cut

- Grain: Zirconia or ceramic for cold cutting

- Thickness: We recommend 1.0-1.6 mm for minimal heating

- Technique: Avoid prolonged contact, work in short passes

Using conventional discs for stainless steel leads to the appearance of rust in the cutting area and the loss of the metal's anti-corrosion properties.

How to store abrasive wheels?

Proper storage ensures the safety and efficiency of the wheels:

- Temperature: 15-25°C, avoid sudden changes

- Humidity: No more than 65%, store in a dry place

- Position: Horizontally on a flat surface, do not place on an edge

- Light: Avoid direct sunlight

- Shelf life: Typically 3 years from date of manufacture (listed on label)

Important: Before use, inspect the wheel for cracks, chips or deformations. Damaged wheels must not be used!

Need a consultation?

Our experts will help you choose the optimal abrasive for your task.