Cut-off wheels from the manufacturer and their advantages

If the manufacturer of cutting wheels is reliable enough, then the wheel will increase work productivity and perform more and better operations. A novice master can work with cutting wheels, when you need to prepare simple products, an introductory briefing is enough.

It is easy to distinguish between them since there is a classification by purpose:

- Reinforced wheels with a diameter of 115-230 mm, the maximum working speed reaches 80 m / s. They are used in everyday life and for small needs in construction, mainly for angle grinders.

- 250-900 mm - diameter of reinforced circles intended for work on stationary machines, developing a speed of up to 100 m / s. They are installed on premises for the production of serial batches.

Before you buy abrasive wheels wholesale or retail, you need to decide on the brand and type of the required device. Therefore, it is worth learning in more detail about what types exist and what they are used for.

Recommendations for using cut-off wheels

For each circle, there are a number of technical and structural requirements, as well as operational safety. It is worth highlighting the following recommendations:

- The outer diameter of the circle must be selected for a specific device so that its parameters do not exceed the maximum allowable values provided by the manufacturer.

- The thickness is selected based on the material and section of the workpiece.

- Control of permissible deviations in the height of the circle.

- Correct wheel run-out readings. Deviations from the standards can lead to serious changes in the quality of work.

- The technical level of construction, moderate imbalance. Otherwise, there is a risk of increased vibration and rapid destruction of the moving part.

- The appearance must be such that it can be called integral, high-quality, which means the absence of visible defects, cracks, and extraneous holes.

- Limiting speed level in operation. It depends on whether the circle will be created with or without a bakelite bond, or with a vulcanite binder.

- The scope of use of the products must correspond to the intended purpose. It's about cutting metal and non-metal.

- Correspondence of the cutting coefficient indicators to the requirements of EN12413.

- Safety check of each unit.

- Make sure to comply with the symbols on the surface and packaging.

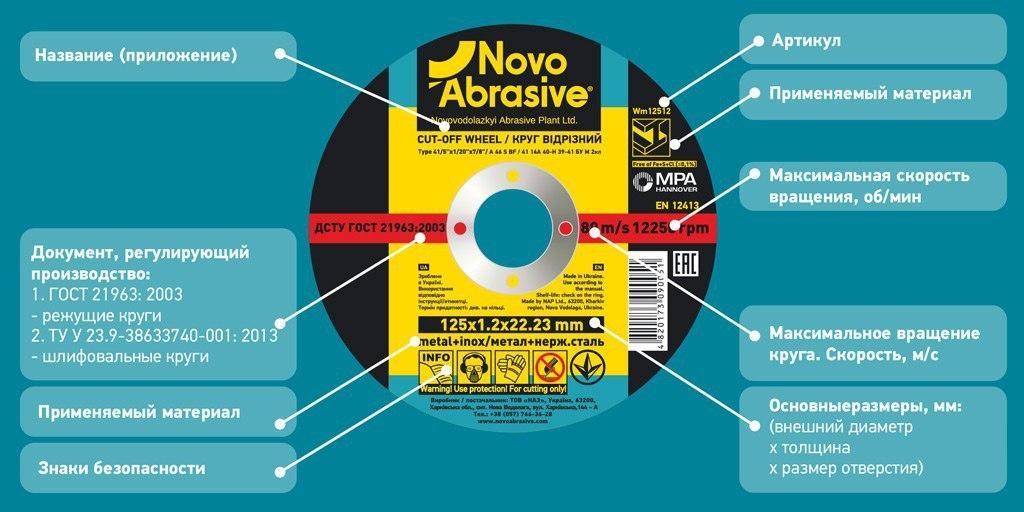

Controlling the presence and validity of the marking is an important part of the inspection process before buying wholesale or retail edging wheels. Therefore, it is worth understanding these combinations of letters, numbers.

Marking

If the discs have been manufactured according to standards and requirements, the packaging must be marked:

- name of the manufacturer;

- producing country;

- image of a round object;

- date of issue, as well as expiration dates;

- availability of a certificate;

- security guarantee;

- equipment rotation speed limit in operation;

- colour coding of device capabilities in the form of a tape;

- the presence of a barcode.

If one or several items are missing, you should think about the advisability of buying a product of dubious reliability. After all, buying cutting wheels in bulk is not a problem, it is more difficult to realize your plans later.

How to use abrasive discs safely

You can buy abrasive wheels in bulk from the manufacturer, knowing that he followed all the necessary rules in the manufacture.

When using the tool, you must take precautions:

- you can not use cutting wheels as grinding equipment, use the side surface of the product;

- monitor proper storage and disposal as the expiration date expires;

- refuse to use discs that are damaged;

- full protective equipment of the employee is obligatory;

- constant monitoring of the correctness of installation and the absence of deviations from the norm in the operation of the mechanism;

- running the disk before starting work for at least 2 minutes.

It is important to buy cutting discs for metal where the seller can guarantee the reliability and safety of the wheel. Buy only what you are sure of!

>>> Read more about Abrasive wheel markings

>>> Read more about Safe use of abrasive cut-off wheels